For any serious candle maker, investing in a professional wax melter is the pivotal step from inconsistent craft to predictable, high-quality production. This specialized equipment provides precise temperature control, enhanced safety, and operational efficiency that hobbyist methods simply cannot match, allowing you to focus on artistry and scaling your business.

The core decision to upgrade to a professional wax melter isn't just about melting wax faster. It's about gaining absolute control over your most critical variable—temperature—which is the foundation for producing a safe, consistent, and high-quality candle every single time.

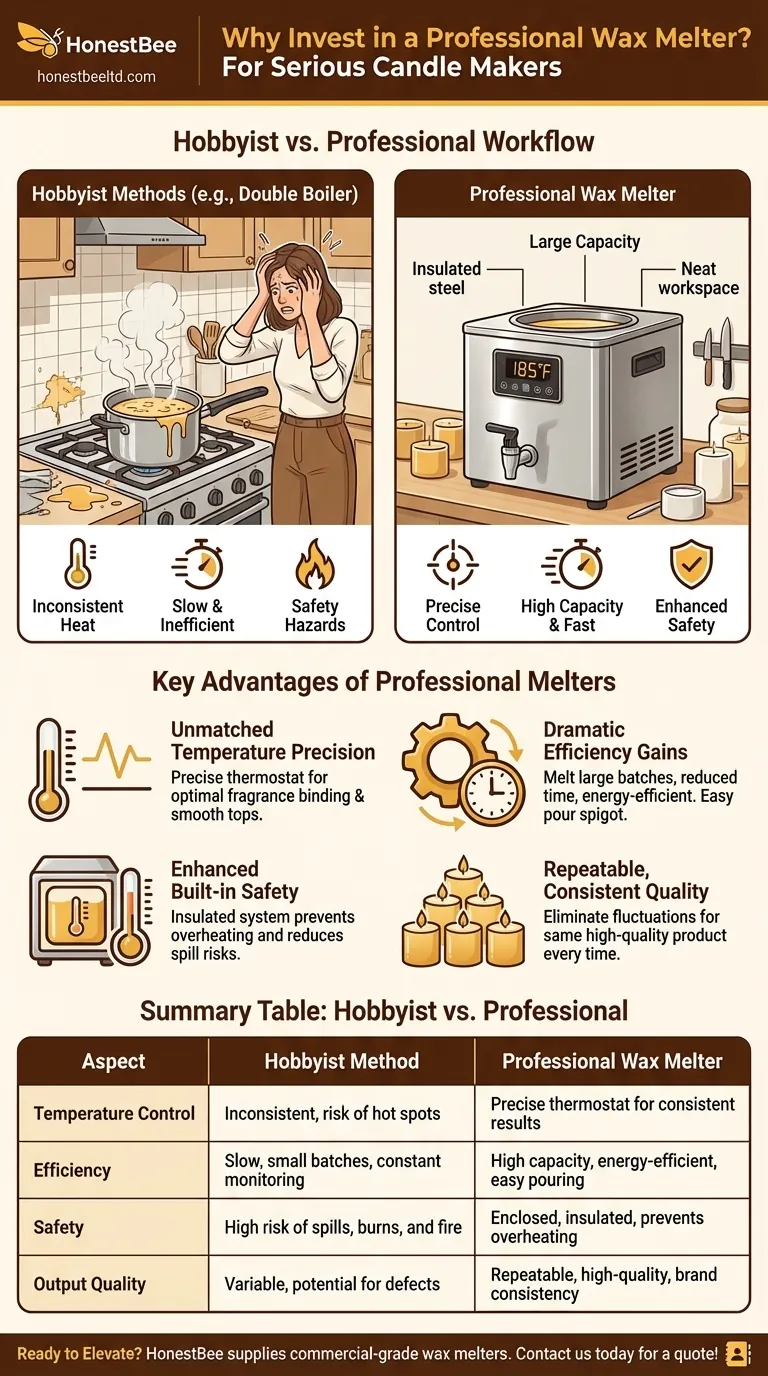

The Core Problem with Hobbyist Methods

Before understanding the value of a professional melter, it's essential to recognize the limitations of common starting methods, like the double boiler on a stovetop. These methods create production bottlenecks and introduce quality control issues.

Inconsistent and Unreliable Heat

A double boiler provides indirect but often uneven heat. This can lead to hot spots that scorch your wax, degrading its quality and potentially altering its chemical structure.

Inconsistent temperatures also make it difficult to add fragrance oil at the optimal moment, resulting in poor scent throw in the final product.

Inefficient and Slow

Melting wax in small batches on a stove is time-consuming. As your order volume grows, this process quickly becomes the primary bottleneck, limiting your ability to scale production efficiently.

Constantly monitoring a pot on the stove consumes your attention, pulling you away from other critical tasks like preparing vessels or wicking.

Significant Safety Hazards

An open pot of hot wax on a stove is an inherent risk. It creates the potential for dangerous spills, severe burns, or even fires if the wax overheats to its flashpoint. This risk is unacceptable in a professional or commercial setting.

Key Advantages of a Professional Wax Melter

A dedicated wax melter is engineered to solve these problems directly, transforming your workflow and elevating your product quality.

Unmatched Temperature Precision

The single most important feature is a built-in, reliable thermostat. This allows you to set and hold wax at a precise temperature indefinitely.

This control is critical for ensuring proper fragrance oil binding, achieving smooth tops on your candles, and ensuring proper glass adhesion, which are all hallmarks of a premium candle.

Dramatic Gains in Efficiency

Professional melters come in various capacities, allowing you to melt large quantities of wax at once. This drastically reduces the time spent on the melting process.

Most units are well-insulated, making them more energy-efficient than a stovetop. They also feature a spigot or tap for easy, mess-free pouring, which speeds up the entire production line.

Enhanced and Built-in Safety

These melters are designed with safety as a priority. They are enclosed, insulated systems that significantly reduce the risk of spills and burns compared to an open pot.

The thermostatic control prevents the wax from ever reaching a dangerous temperature, offering peace of mind and a safer working environment.

Repeatable, Consistent Quality

By eliminating temperature fluctuations, a professional melter ensures that every candle you pour is made under the exact same conditions.

This consistency is the bedrock of a reputable brand. Your customers will receive the same high-quality product with every purchase, building trust and loyalty.

Understanding the Trade-offs

While the benefits are clear, objectivity requires acknowledging the considerations that come with this investment.

The Initial Investment

A professional wax melter is a significant upfront cost compared to a simple pot. You must view it as a capital investment in your business infrastructure, not just a tool.

Space and Power Requirements

These units are larger than a double boiler and require a dedicated, stable surface to operate on. Larger models may also have specific power requirements that need to be considered.

Cleaning and Maintenance

While the spigot simplifies pouring, the melter itself must be cleaned regularly, especially when switching between different types of wax or fragrances. This is a necessary step to prevent cross-contamination.

Making the Right Choice for Your Goal

Upgrading to a professional melter is a strategic decision that should align with your specific objectives.

- If your primary focus is scaling a business: The efficiency and capacity gains are non-negotiable for meeting growing demand and reducing your cost per unit.

- If your primary focus is perfecting product quality: The precise temperature control is the only way to achieve truly consistent results and eliminate defects.

- If your primary focus is creating a safe, professional workspace: The built-in safety features of a dedicated melter are essential for mitigating risk and operating responsibly.

Ultimately, a professional wax melter is the tool that empowers you to transition from simply making candles to running a predictable and scalable candle-making operation.

Summary Table:

| Aspect | Hobbyist Method (e.g., Double Boiler) | Professional Wax Melter |

|---|---|---|

| Temperature Control | Inconsistent, risk of hot spots | Precise thermostat for consistent results |

| Efficiency | Slow, small batches, constant monitoring | High capacity, energy-efficient, easy pouring |

| Safety | High risk of spills, burns, and fire | Enclosed, insulated, prevents overheating |

| Output Quality | Variable, potential for defects | Repeatable, high-quality, brand consistency |

Ready to elevate your candle-making operation? A professional wax melter is the cornerstone of a scalable, safe, and high-quality business. HONESTBEE supplies commercial-grade wax melters and beekeeping equipment to serious candle makers and distributors through wholesale-focused operations. Let us help you build a more efficient and profitable business. Contact HONESTBEE today to discuss your equipment needs and request a quote!

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

People Also Ask

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation

- How does the machine flatten the beeswax? A Guide to Roller and Press Methods

- What is the final step in making beeswax foundation sheets? Achieving Perfect Fit for a Productive Hive

- What is the process for purifying beeswax after removing it from a hive? A Simple Two-Stage Method for Pure Wax

- Why might a commercial beekeeper prefer an electric beeswax melter? Maximize Profit with Speed & Scale