Beekeeping demands gear that protects without restricting—a balance modern bee suits achieve through cutting-edge materials and ergonomic engineering. This article breaks down the science behind today’s most advanced bee suits, offering beekeepers actionable insights to choose equipment that enhances productivity while minimizing fatigue.

The Science Behind Bee Suit Protection

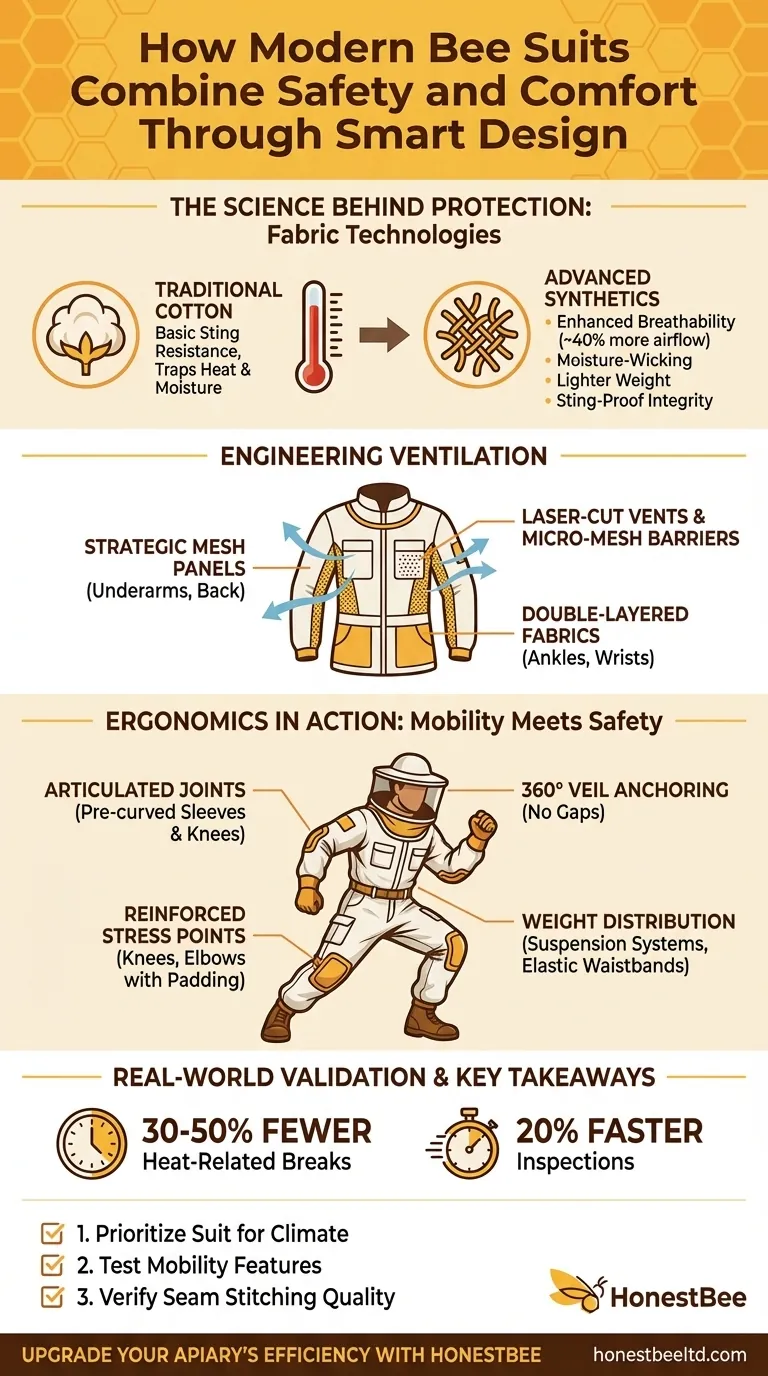

Fabric Technologies: From Traditional Cotton to Advanced Synthetics

Traditional cotton bee suits provided basic sting resistance but often trapped heat and moisture. Contemporary designs use synthetic blends like polyester-microfiber composites, which offer:

- Enhanced breathability without sacrificing sting-proof integrity

- Moisture-wicking properties to keep beekeepers dry during long hive inspections

- Lighter weight for reduced heat stress

Research shows these materials can withstand hundreds of sting attempts while improving airflow by approximately 40% compared to older cotton models.

Engineering Ventilation Without Compromising Security

Strategic mesh panels in high-heat zones (underarms, back) maintain airflow, while double-layered fabrics at sting-prone areas (ankles, wrists) add protection. For example, some suits integrate:

- Laser-cut ventilation ports with micro-mesh barriers

- Zippered vents adjustable for varying weather conditions

Ergonomics in Action: Mobility Meets Safety

Articulated Joints and Strategic Reinforcements

Modern suits mimic natural movement patterns through:

- Pre-curved sleeves and knees to reduce fabric tension during bending/lifting

- Reinforced stress points (knees, elbows) with abrasion-resistant padding

- 360° veil anchoring to prevent gaps when turning your head

Weight Distribution and Fatigue Reduction

Prolonged wearability hinges on balancing protection and comfort. Innovations include:

- Modular designs allowing beekeepers to detach hoods/jackets as needed

- Suspension systems that shift weight from shoulders to hips

- Elasticized waistbands preventing suit sagging during repetitive motions

Real-World Validation: Beekeeper Case Studies

Commercial apiaries report 30–50% fewer heat-related breaks when using suits with advanced ventilation. One distributor noted:

"Beekeepers using ergonomic suits complete hive inspections 20% faster due to unrestricted movement."

Key takeaways for buyers:

- Prioritize suits matching your climate (e.g., heavier fabrics for cooler regions)

- Test mobility features (raise arms, kneel) before purchasing

- Verify seam stitching quality—poorly sealed seams are common failure points

Upgrade Your Apiary’s Efficiency with HONESTBEE

Commercial beekeepers and distributors trust HONESTBEE’s wholesale-focused beekeeping supplies for durable, research-backed gear. Explore our bee suits engineered for all-day comfort and unmatched protection—because your productivity shouldn’t be stung by subpar equipment.

Visual Guide

Related Products

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

- Yellow Plastic Bucket Pail Perch for Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Professional Insulated Winter Hive Wrap for Beekeeping

- Automatic Honey Flow Beehive 4 Frame Mini Hive for Beekeeping

Related Articles

- Essential Beekeeping Equipment for Beginners: Functions, Selection, and Best Practices

- How Thoughtful Pocket Design Transforms Hive Inspections for Beekeepers

- How to Relocate Beehives Safely: A Science-Backed Guide for Beekeepers

- Why Your Plastic Frames Are Warping—And Costing You More Than You Think

- The Unclimbable Fortress: A Systems Approach to Protecting Hives from Ants