It’s a familiar scene for any growing beekeeping operation. You’re in the bee yard, ready for a full day of inspections. You try to swap a super from a new stack onto an established hive, but it doesn’t sit right. There’s a gap. You grab another lid, and it wobbles. A frame that fit perfectly in one box is now tight in another, risking a rolled queen.

Each mismatched piece is a small frustration, but across dozens or hundreds of hives, it becomes a systemic drag on your entire operation. You're left wondering: "We build them all the same way. Why are they all slightly different?"

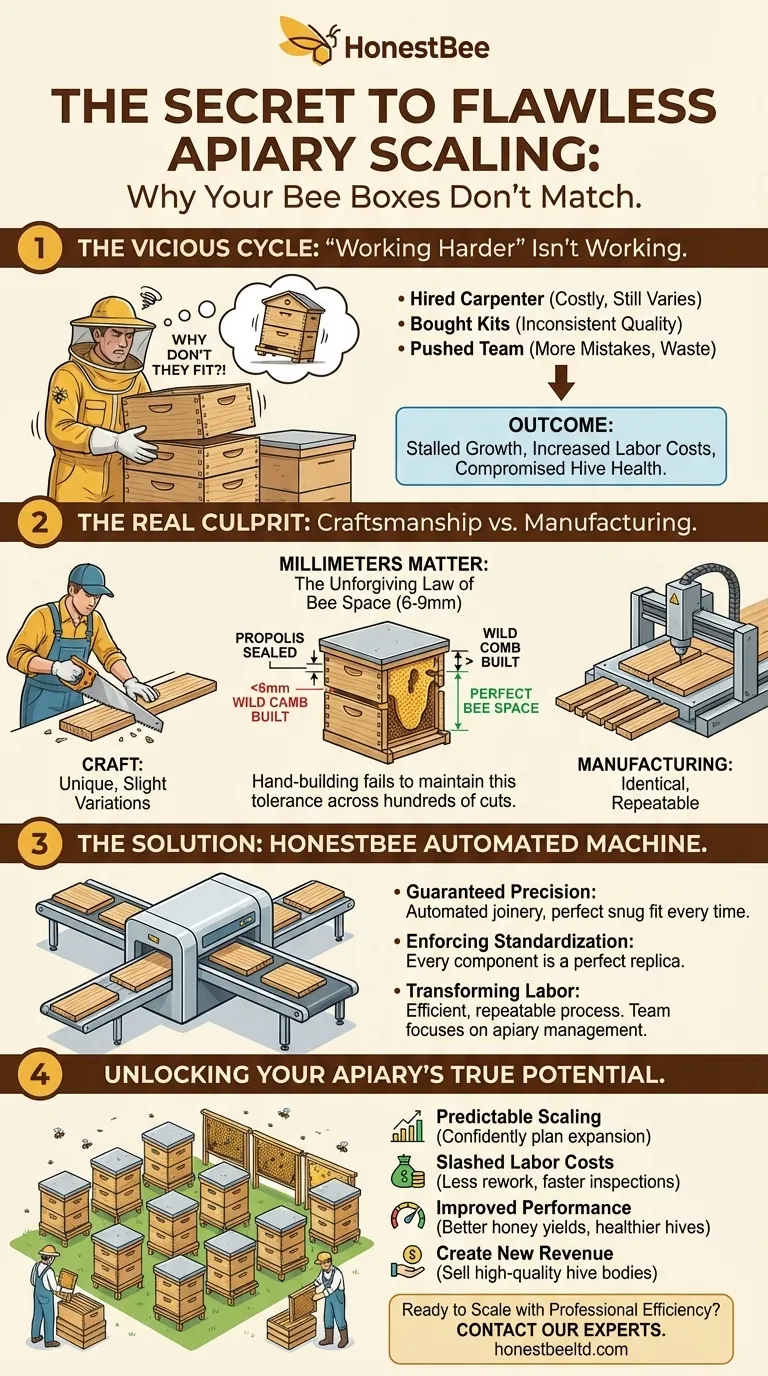

The Vicious Cycle: Why "Working Harder" Isn't Working

If you're facing this problem, you've likely already tried the obvious fixes. You might have:

- Hired a skilled carpenter: This improved quality initially, but it was expensive, and even a great craftsman has slight variations from piece to piece. It’s not a scalable solution.

- Bought pre-cut kits: The quality was a mixed bag. Some suppliers were good, others weren't. The cost per box ate directly into your profit margins, making expansion feel financially punishing.

- Pushed your team to build faster: This only led to more mistakes, lower morale, and wasted lumber.

These efforts, while logical, fail to solve the underlying problem. The business consequences are significant and concrete:

- Stalled Growth: Your plans to expand from 100 to 300 hives are on hold because you simply can't produce reliable equipment fast enough.

- Increased Labor Costs: Inspections take longer. Time is wasted searching for compatible parts. Staff are tied up in the workshop instead of managing the bees.

- Compromised Hive Health: Inconsistent boxes mean inconsistent "bee space," leading to burr comb and propolis buildup that makes inspections disruptive and stressful for your colonies.

You're stuck in a loop, investing more time and money just to maintain a state of frustrating inefficiency.

The Real Culprit: Craftsmanship vs. Manufacturing

Here is the truth that often gets missed: The root cause of inconsistency is not a lack of skill; it's a reliance on craftsmanship where manufacturing is required.

Building a single, beautiful bee box by hand is a craft. Building 500 identical bee boxes that are perfectly interchangeable is a manufacturing process. A craft embraces slight, unique variations. A manufacturing process is designed to eliminate them entirely.

Why Millimeters Matter: The Unforgiving Law of Bee Space

The entire world of a honeybee is dictated by a precise measurement known as "bee space"—a gap of 6 to 9 millimeters.

- If a gap is smaller, bees will seal it with propolis.

- If a gap is larger, they will build wild comb in it.

When you build boxes by hand, maintaining this tolerance across hundreds of cuts and joints is nearly impossible. A saw blade that’s a fraction of a millimeter off, a slight angle change in a jig—these tiny errors compound. The result is boxes that are almost right, but not identically right.

This is why the "common solutions" fail. They are attempts to improve the craft (a better carpenter, better kits) instead of changing the process. They address the symptom—the need for more boxes—but ignore the disease: the lack of perfect, repeatable standardization.

From Carpenter to Manufacturer: The Role of the Right Machine

To truly solve this problem, you don't need a better craftsman. You need a system that removes human variation from the critical steps. You need a tool engineered to deliver absolute precision, not just once, but on the thousandth cut as perfectly as the first.

This is the purpose of a bee box-making machine. It’s not just a "faster saw." It’s a specialized system designed based on a deep understanding of apiary management. It's built to solve the core problem of standardization that plagues every scaling beekeeping operation.

An automated machine from HONESTBEE directly addresses the root cause by:

- Guaranteeing Precision: It automates the most complex part of hive construction—the joinery. Every finger joint is cut to the exact same dimension, ensuring a perfect, snug fit every time. This makes the "bee space" correct by default.

- Enforcing Standardization: Every component produced is a perfect replica of the last. A lid made in January will fit perfectly on a hive body made in June. A super from pallet A is interchangeable with one from pallet Z.

- Transforming Labor: It turns a high-skill, time-consuming task into a safe, repeatable, and efficient process. Your team can now focus on assembly and apiary management, not complex woodworking.

This isn't just about convenience. It’s a strategic shift from being a bee keeper who builds boxes, to a bee business that manufactures its own high-quality assets.

Beyond the Box: Unlocking Your Apiary's True Potential

Once you solve the fundamental problem of equipment inconsistency, you don't just get better boxes. You unlock a new level of operational capacity.

Suddenly, you can:

- Scale Predictably: Confidently plan your expansion, knowing your biggest equipment bottleneck has been eliminated.

- Slash Labor Costs: Reduce time spent on frustrating inspections and workshop rework, reallocating that time to revenue-generating activities.

- Improve Apiary Performance: With less disruptive inspections and healthier hives, you can expect better honey yields and overall colony strength.

- Create New Revenue: With your new production capacity, you can become a local supplier of high-quality hive bodies, turning a cost center into a profit center.

Solving your hive production isn't just about wood and nails; it's about building a stable foundation for your business to grow. If you're ready to move past the limitations of manual production and scale your operation with professional-grade efficiency, our team can help you analyze your current workflow and identify the right solution. Contact Our Experts.

Visual Guide

Related Products

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

Related Articles

- Beyond the Scrape: The Silent Killer in Your Beehives and How to Stop It

- The Apiary as a System: Why Your Hive Tool is More Than Just Steel

- The Physics of Propolis: Why Your Hive Tool Choice Defines Your Apiary's Workflow

- More Than Steel: How a Simple Hive Tool Dictates the Success of an Apiary

- The Art of Intervention: A Systems Approach to Beehive Maintenance