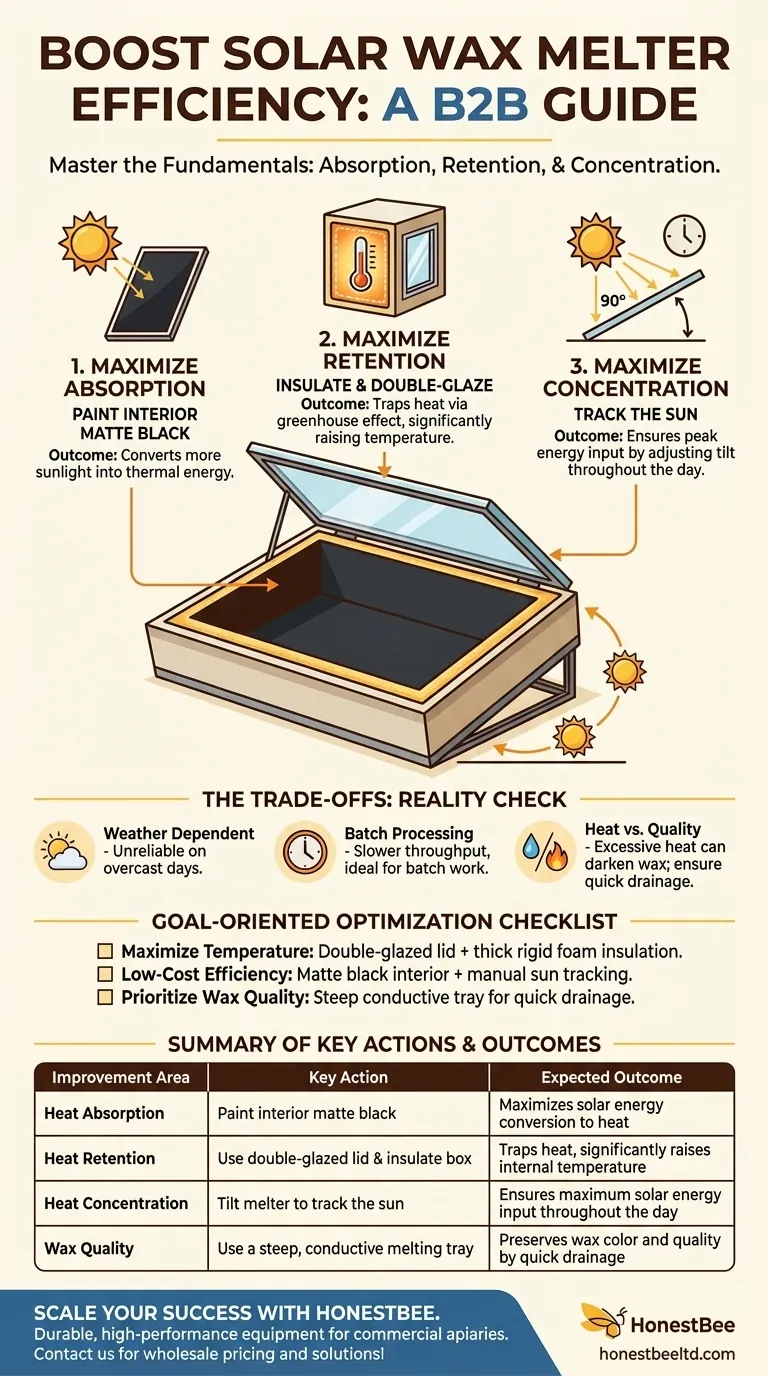

To improve the efficiency of a solar wax melter, you must focus on three core principles: maximizing heat absorption, retaining that heat, and concentrating it effectively. The most direct ways to achieve this are by painting the interior of the melter a matte black, insulating the box to prevent heat loss, and tilting the entire unit to directly face the sun throughout the day.

A solar wax melter operates on simple physics. Its efficiency isn't determined by complex mechanisms, but by how well its design absorbs solar energy, traps the resulting heat, and transfers that heat to the beeswax. Mastering these fundamentals is the key to faster and more effective melting.

The Core Principles of Solar Heat Transfer

A solar melter is essentially a super-insulated, sun-powered oven. Its performance hinges on how well it manages energy. Understanding the principles behind this allows you to diagnose and improve your specific setup.

Maximizing Absorption: The Role of Color

The process begins with absorbing as much solar energy as possible. Dark, matte surfaces are superior absorbers of the sun's radiation compared to light-colored or shiny surfaces, which reflect energy away.

Painting the entire interior of your melter—including the melting tray—a matte black is the single most important step for improving heat absorption. This ensures the maximum amount of incoming sunlight is converted into thermal energy inside the box.

Maximizing Retention: The Greenhouse Effect and Insulation

Once the sunlight is converted to heat, you must trap it. This is achieved through two mechanisms: the greenhouse effect and physical insulation.

The glass or polycarbonate lid creates a greenhouse effect. It allows short-wave solar radiation to pass through but is less permeable to the long-wave infrared radiation (heat) that the black interior emits, trapping it inside. A double-glazed glass lid is significantly more effective, creating an insulating air gap that can raise internal temperatures dramatically, sometimes up to 120°C (248°F) in direct sun.

The walls and floor of the melter box must also be well-insulated. Without insulation, the trapped heat will simply escape through conduction. Adding foam board or other insulating materials to the outside or within the walls of the box prevents this heat leak, keeping the internal temperature high.

Maximizing Concentration: Proper Angle and Positioning

For the sun's energy to be absorbed, it must first enter the box. The amount of energy entering is highest when the sun's rays strike the glass lid at a perpendicular (90-degree) angle.

To achieve this, the melter must be tilted to face the sun directly. As the sun moves across the sky, this optimal angle changes. For peak efficiency, you should adjust the melter's position and tilt a few times throughout the day to track the sun's path.

Understanding the Trade-offs

While highly effective and sustainable, solar wax melters have inherent limitations that are important to acknowledge.

Dependence on Weather

The most significant limitation is the absolute reliance on strong, direct sunlight. Performance drops dramatically on overcast days, making them unreliable in many climates or during certain seasons. Operation is limited to daylight hours on clear days.

Processing Speed and Volume

Solar melters are a form of batch processing and are inherently slow. The gentle melting process produces very high-quality, light-colored beeswax, but it cannot match the throughput of electric or gas-powered melters. They are ideal for hobbyists or small-scale beekeepers, not large commercial operations.

Wax Quality vs. Heat

While high heat is the goal for efficiency, excessive temperatures can darken or "cook" the beeswax, reducing its quality. A well-designed melter allows the liquid wax to flow away from the comb and the primary heat zone quickly, collecting in a cooler pan. This preserves the wax's natural color and aroma.

Making the Right Choice for Your Goal

Apply these principles with a clear objective in mind. Use this checklist to optimize your melter for peak performance.

- If your primary focus is maximum temperature: Invest in a double-glazed glass lid and add a thick layer of rigid foam insulation to the exterior of the melter box.

- If your primary focus is low-cost efficiency: Ensure the interior is painted matte black and commit to adjusting the melter's angle to track the sun throughout the day.

- If your primary focus is wax quality: Confirm your melter has a steeply-angled tray made of a conductive material (like stainless steel) that allows melted wax to immediately drain into a collection pan.

By systematically applying these principles of heat absorption, retention, and concentration, you can transform your solar wax melter into a highly efficient tool.

Summary Table:

| Improvement Area | Key Action | Expected Outcome |

|---|---|---|

| Heat Absorption | Paint interior matte black | Maximizes solar energy conversion to heat |

| Heat Retention | Use double-glazed lid & insulate box | Traps heat, significantly raises internal temperature |

| Heat Concentration | Tilt melter to track the sun | Ensures maximum solar energy input throughout the day |

| Wax Quality | Use a steep, conductive melting tray | Preserves wax color and quality by quick drainage |

Ready to upgrade your beekeeping operation? For commercial apiaries and distributors, efficiency is key. HONESTBEE supplies the durable, high-performance equipment you need to scale your success. From insulated hive components to tools that streamline your workflow, our wholesale-focused operations are designed to support your business. Contact HONESTBEE today to discuss your equipment needs and wholesale pricing!

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Professional Thermostatic Conical Honey Melter

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

People Also Ask

- Why is preserving honeycomb integrity important, and how do automated extractors help? Boost Hive Health & Honey Yields

- What is the purpose of decanting in honey extraction? Achieve a Purer, More Stable Honey Product

- How long does it take to extract honey with an electric extractor? Cut extraction time to minutes.

- Which type of extractor is better for medium to large-scale honey processing? Boost Efficiency with Electric Radial Extractors

- How long does it take to extract honey with an electric extractor? Automate Your Harvest for Greater Efficiency