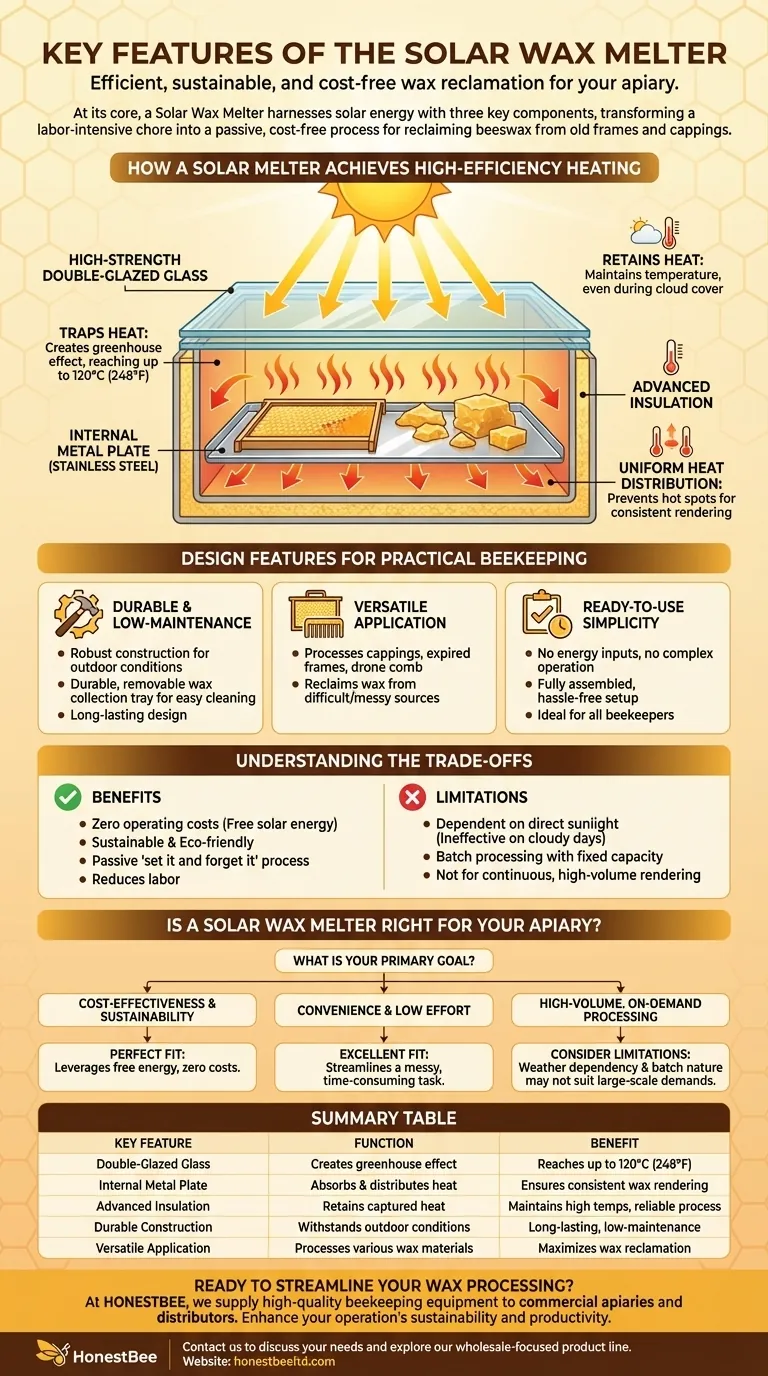

At its core, a Solar Wax Melter is defined by three key features: high-strength double-glazed glass, an internal metal plate for heat distribution, and advanced insulation. These components work in synergy to harness solar energy, efficiently melting beeswax from old frames and cappings without any ongoing operating costs.

The Solar Wax Melter isn't just a piece of equipment; it's a strategic tool for beekeepers. It transforms a labor-intensive chore into a passive, cost-free process by leveraging a simple design to capture and concentrate the sun's energy for maximum wax reclamation.

How a Solar Melter Achieves High-Efficiency Heating

A solar melter’s effectiveness is not accidental; it’s the result of specific design choices that maximize the power of the sun. Understanding how these elements work together clarifies its value.

The Role of Double-Glazed Glass

The high-strength, double-glazed glass lid is the engine of the device. It creates a greenhouse effect, allowing solar radiation to enter while trapping the resulting heat inside.

This design enables the interior to reach temperatures as high as 120°C (248°F) in direct sunlight, well above the melting point of beeswax.

Uniform Heat Distribution

Inside, a stainless steel plate or tray serves a dual purpose. It provides a surface for the frames or wax to rest on and, more importantly, it absorbs and distributes heat evenly.

This uniform heating prevents hot spots and ensures that all the wax melts at a consistent rate, improving the overall efficiency of the rendering process.

Advanced Insulation for Temperature Retention

High-quality melters are built with advanced insulation within their walls. This feature is critical for retaining the heat captured by the glass.

Effective insulation means the melter can maintain high temperatures even during brief moments of cloud cover, making the process more reliable and faster.

Design Features for Practical Beekeeping

Beyond its heating mechanism, the Solar Wax Melter is designed with the practical needs of a beekeeper in mind. Its features prioritize durability, ease of use, and versatility.

Durable, Low-Maintenance Construction

The melter is crafted from durable materials designed to withstand outdoor conditions and high internal temperatures for years.

It also features a durable wax tray that collects the rendered liquid wax. This tray is designed to be easy to remove and clean, simplifying the final step of the process.

Versatile Application

This tool is not limited to just wax cappings. Its primary value for many is its ability to process expired frames, drone comb, and other wax-containing materials.

This versatility allows beekeepers to reclaim valuable wax from sources that would otherwise be difficult or messy to handle.

Ready-to-Use Simplicity

Most Solar Wax Melters arrive fully assembled and ready to use out of the box. This hassle-free setup makes it an ideal tool for beginners and experienced beekeepers who value efficiency.

Because it requires no energy inputs or complex operation, it is one of the most straightforward pieces of equipment in an apiary.

Understanding the Trade-offs

While highly effective, the Solar Wax Melter operates within a specific set of constraints. Objectively assessing these limitations is key to determining if it fits your workflow.

The Dependency on Sunlight

The most significant limitation is its absolute reliance on direct, strong sunlight. The device is ineffective on cloudy, overcast, or rainy days.

This means your wax processing schedule is dictated entirely by the weather, which may not be ideal for operations requiring predictable output.

Batch Processing and Capacity

Solar melters are batch processors with a fixed capacity, typically holding a few frames at a time. While different sizes are available, they are not designed for continuous, high-volume rendering.

For small-scale or hobbyist beekeepers, this is rarely an issue. For large commercial apiaries, a solar melter is often a supplementary tool rather than a primary one.

Is a Solar Wax Melter Right for Your Apiary?

To make the right choice, align the features of the tool with the primary goals of your beekeeping operation.

- If your primary focus is cost-effectiveness and sustainability: This is the perfect tool, as it leverages free solar energy with zero operating costs.

- If your primary focus is convenience and low effort: Its "set it and forget it" nature makes it an excellent fit for streamlining a messy and time-consuming task.

- If your primary focus is high-volume, on-demand processing: You must consider its limitations, as its weather dependency and batch nature may not meet the demands of a large-scale commercial operation.

Ultimately, the Solar Wax Melter provides an elegant and effective solution for turning a necessary chore into a sustainable asset for your apiary.

Summary Table:

| Key Feature | Function | Benefit |

|---|---|---|

| Double-Glazed Glass | Creates a greenhouse effect, trapping heat | Reaches temperatures up to 120°C (248°F) for efficient melting |

| Internal Metal Plate | Absorbs and distributes heat evenly | Prevents hot spots, ensures consistent wax rendering |

| Advanced Insulation | Retains captured heat inside the unit | Maintains high temperatures even during brief cloud cover |

| Durable Construction | Built to withstand outdoor conditions and high heat | Long-lasting, low-maintenance tool for years of use |

| Versatile Application | Processes frames, cappings, and other wax materials | Maximizes wax reclamation from various sources |

Ready to streamline your wax processing with a reliable, cost-free solution?

At HONESTBEE, we specialize in supplying high-quality beekeeping equipment to commercial apiaries and distributors. Our Solar Wax Melters are designed to help you reclaim valuable wax efficiently, reducing labor and eliminating energy costs.

Let us help you enhance your operation's sustainability and productivity. Contact our team today to discuss your needs and explore our wholesale-focused product line.

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

People Also Ask

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation

- What is the process for purifying beeswax after removing it from a hive? A Simple Two-Stage Method for Pure Wax

- How does the beeswax flatting and embossing machine prepare the wax for processing? Achieve Perfectly Uniform Wax Sheets

- Why might a commercial beekeeper prefer an electric beeswax melter? Maximize Profit with Speed & Scale

- What is the final step in making beeswax foundation sheets? Achieving Perfect Fit for a Productive Hive