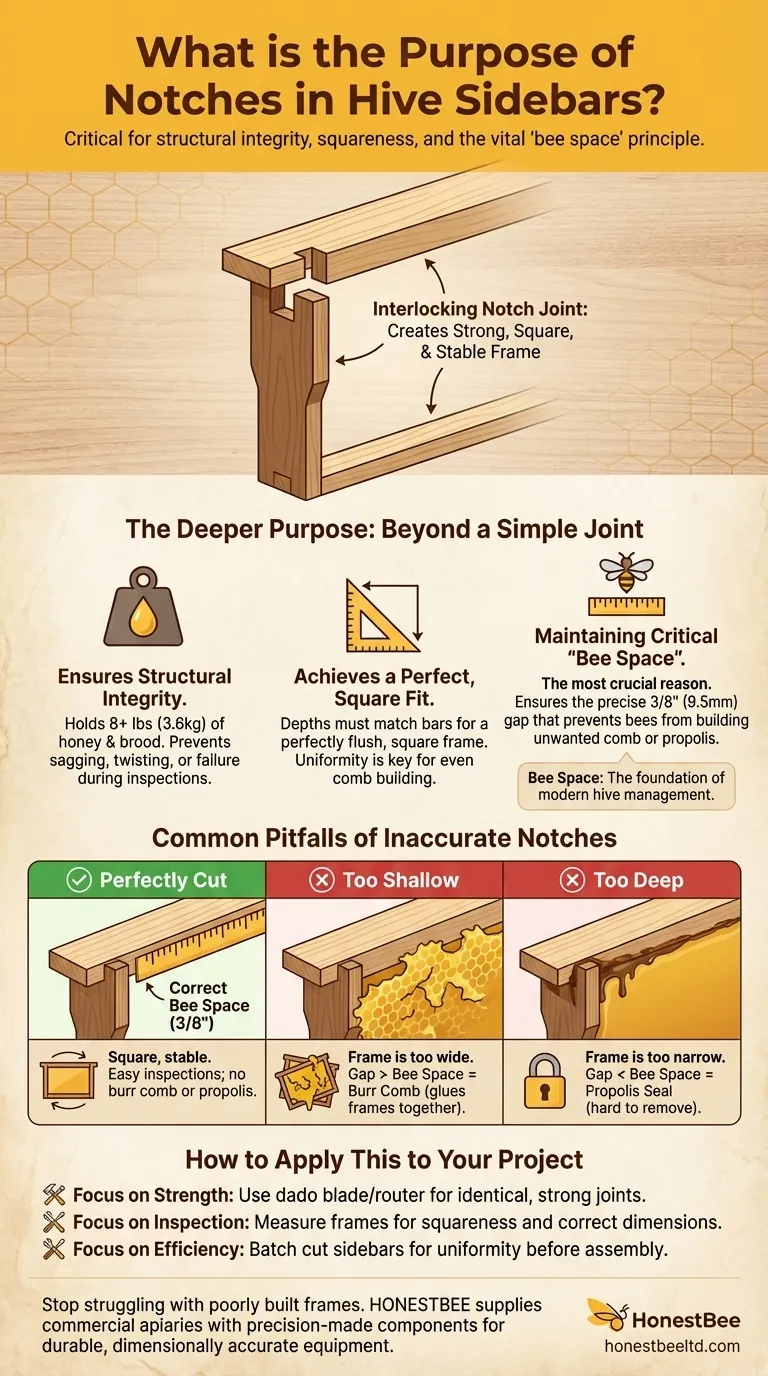

In beekeeping, the notches cut into the sidebars of a hive frame serve a critical structural purpose. These precisely cut recesses are designed to hold the top and bottom bars, creating a strong, interlocking joint that ensures the frame remains square and dimensionally stable under the significant weight of honey and brood.

The notches are not merely for assembly; they are fundamental to creating a strong, uniform frame. This uniformity is the key to maintaining the correct "bee space" throughout the hive, which is the single most important principle for easy and effective hive management.

The Deeper Purpose: Beyond a Simple Joint

While the immediate function of a notch is to connect wooden parts, its true value in a beehive frame lies in how it impacts bee behavior and the beekeeper's ability to work with the hive.

Ensuring Structural Integrity

A single deep frame can weigh over eight pounds (3.6 kg) when full of honey. The simple interlocking joint created by the notches provides far more strength and rigidity than a basic butt joint secured with a nail.

This strength prevents the frame from sagging, twisting, or falling apart during hive inspections, which would be catastrophic for the colony and the beekeeper.

Achieving a Perfect, Square Fit

The depth of the notch must precisely match the thickness of the top and bottom bars. This ensures the assembled frame is perfectly square and flush.

A wobbly or out-of-square frame is difficult for bees to build on evenly and can disrupt the hive's carefully organized structure.

Maintaining Critical "Bee Space"

This is the most crucial reason for precise notches. "Bee space" is a specific gap, typically 3/8 of an inch (about 9.5 mm), that bees will not build comb in or seal with propolis. Modern hives are built entirely around this principle.

If notches are cut incorrectly, the assembled frame's width will be wrong. This throws off the bee space between adjacent frames, forcing the beekeeper to constantly battle unwanted comb and glue.

Common Pitfalls of Inaccurate Notches

Precision is not optional when building frames. Even small errors in the notches can lead to significant problems that compound over time, making hive management frustrating and difficult.

The Problem with Inconsistent Joints

If your notches are not uniform across all your frames, you lose the core benefit of the modern Langstroth hive: interchangeability.

Frames that aren't identical cannot be easily moved between different boxes or hives, severely limiting your management options for swarm control, honey harvesting, and equalization.

When Notches Are Too Shallow

If the notch is not deep enough, the assembled frame will be too wide. The gap between it and the next frame will be larger than the ideal bee space.

Bees will fill this extra space with burr comb—unwanted, irregular wax construction that glues the frames together and gets in the way during inspections.

When Notches Are Too Deep

If the notch is too deep, the assembled frame will be too narrow. This reduces the gap between frames to be smaller than the bee space.

Bees will treat this narrow gap as a crack and seal it shut with propolis, a hard, sticky resin. This effectively glues the frames to each other, making them extremely difficult to remove without jarring the hive and angering the bees.

How to Apply This to Your Project

Your approach to frame construction should be guided by your end goal: a hive that is easy to manage and productive.

- If your primary focus is strength and longevity: Use a table saw with a dado blade or a router with a jig to cut all your notches. This ensures every joint is identical, tight, and strong.

- If your primary focus is ease of inspection: After assembly, measure your frames to confirm they are square and meet standard dimensions. This diligence guarantees correct bee space and saves you immense frustration later.

- If your primary focus is building efficiency: Cut the notches on all your sidebars in a single batch before you begin assembly. This ensures uniformity and is far faster than making individual adjustments.

Ultimately, viewing frame construction as a precision task is foundational to successful and enjoyable beekeeping.

Summary Table:

| Notch Accuracy | Impact on Frame | Result for the Beekeeper |

|---|---|---|

| Perfectly Cut | Square, stable frame with correct bee space. | Easy inspections; no unwanted comb or propolis. |

| Too Shallow | Frame is too wide; gap larger than bee space. | Bees build burr comb, gluing frames together. |

| Too Deep | Frame is too narrow; gap smaller than bee space. | Bees seal frames with hard-to-remove propolis. |

Stop struggling with poorly built frames that disrupt bee space and complicate hive inspections. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with precision-made hive frames and components. Our wholesale-focused operations ensure you receive durable, dimensionally accurate equipment that guarantees correct bee space, prevents burr comb and propolis issues, and saves you time and frustration during every inspection. Contact HONESTBEE today to discuss your wholesale needs and build a more manageable, productive apiary.

Visual Guide

Related Products

- Professional Bee Frame Wiring Tool with Integrated Tensioning System by HONESTBEE

- HONESTBEE Professional Bee Frame Machine for Side Bar Shaping

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- 7 x Auto Bee Flow Hive Frames Plastic Beekeeping Hive Box Supplies

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

People Also Ask

- How are nails prepared for wiring the frame? Master the First Step to a Durable Hive

- What are the arguments for and against wiring beehive frames? Balance Durability and Management Flexibility

- What is the final step in wiring a frame? Secure Lasting Tension for a Durable Hive

- How is the wire tightened in a beekeeping frame? Expert Techniques for Durable Hive Frames

- How is wire tension maintained during frame wiring? Use a Jig for Perfectly Taut Frames