Beekeeping demands gear that protects without compromising comfort—especially during long hive inspections. The right equipment prevents stings while allowing mobility in varying climates. This guide covers selection criteria and maintenance practices to extend your gear’s lifespan, backed by material science and real-world apiary insights.

Essential Protective Gear for Safe Hive Inspections

Suits: Balancing Full-Body Protection with Ventilation

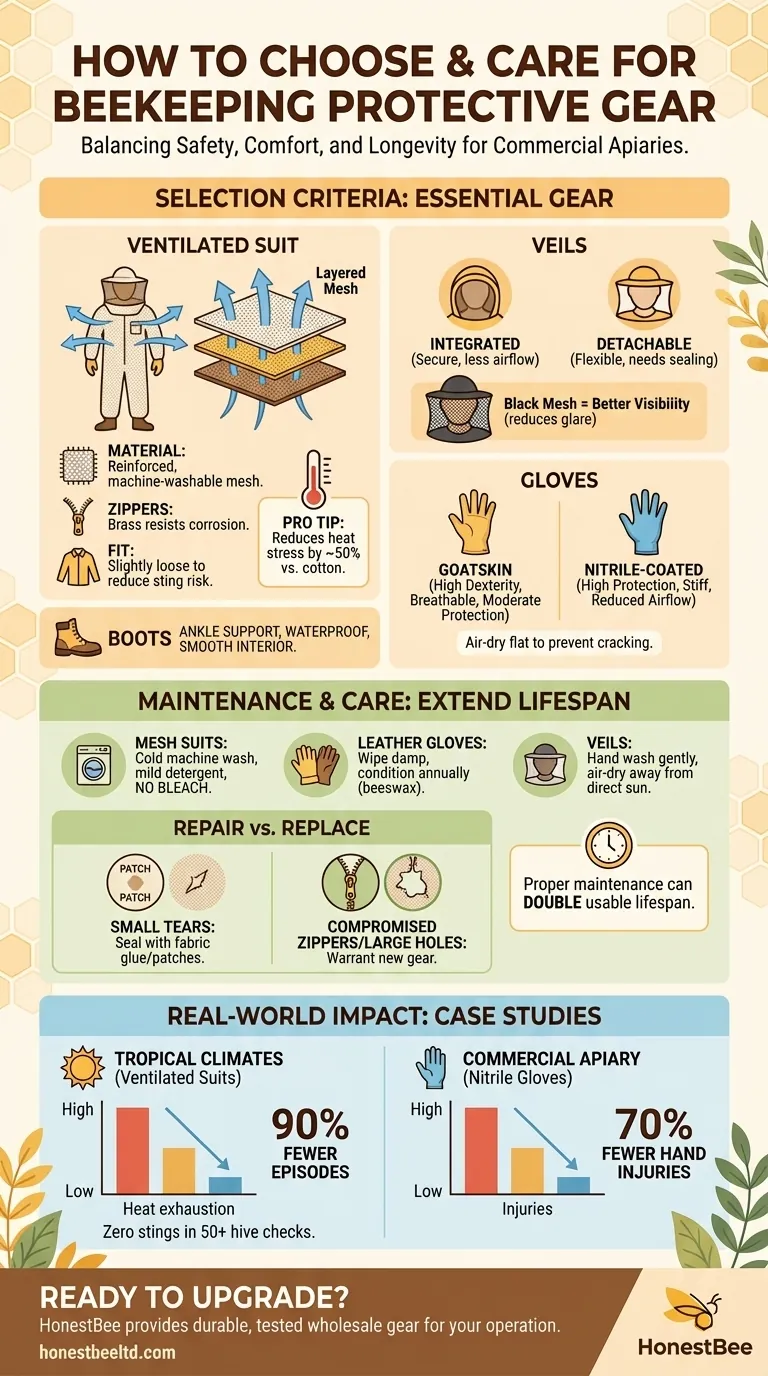

Modern beekeeping suits prioritize airflow without sacrificing safety. Ventilated designs use layered mesh fabric (typically 3 layers) that blocks stings while circulating air—critical for summer inspections. Unlike traditional cotton suits, these allow beekeepers to work comfortably in minimal base layers.

Key considerations:

- Material: Opt for machine-washable mesh with reinforced stitching at stress points (e.g., knees, elbows).

- Zippers: Brass zippers resist corrosion from propolis and honey.

- Fit: A slightly loose fit prevents fabric from pressing against skin, reducing sting risks.

Pro Tip: Ventilated suits eliminate the need for heavy underlayers, cutting heat stress by roughly half compared to standard cotton.

Veils: Integrated vs. Detachable Designs for Visibility and Safety

Veils protect the face and neck while ensuring clear visibility. Two dominant styles exist:

- Integrated veils (built into suits) minimize gaps but may limit airflow.

- Detachable veils offer flexibility but require careful sealing to prevent bee entry.

Choose black mesh over lighter colors to reduce glare and improve visibility during sunny inspections.

Gloves: Material Trade-offs Between Dexterity and Sting Resistance

Glove selection hinges on balancing protection and tactile sensitivity:

| Material | Pros | Cons |

|---|---|---|

| Goatskin | High dexterity, breathable | Moderate sting resistance |

| Nitrile-coated | Excellent sting protection | Reduced airflow, stiff feel |

Maintenance Note: Air-dry gloves flat after washing to prevent material cracking.

Boots: Waterproofing and Ankle Support in Apiary Environments

Apiaries’ uneven terrain demands boots with:

- Ankle support to prevent twists

- Waterproofing for wet grass or morning dew

- Smooth interiors to avoid seams that irritate during prolonged wear

Maintaining Gear to Ensure Long-Term Protection

Cleaning Methods for Different Materials

- Mesh suits: Machine wash cold with mild detergent; avoid bleach (weakens fibers).

- Leather gloves: Wipe with damp cloth; condition annually with beeswax-based products.

- Veils: Hand wash to preserve mesh integrity; air-dry away from direct sunlight.

Repairing Minor Damage vs. Replacement

Assess damage severity:

- Patchable: Small tears in mesh suits can be sealed with fabric glue or patches.

- Replace: Compromised zippers or large holes in sting-resistant layers warrant new gear.

Cost-Saving Insight: Proper maintenance can double a suit’s usable lifespan, delaying replacement costs.

Case Studies: How Proper Gear Prevented Severe Sting Incidents

-

Ventilated Suit in Tropical Climates

A Florida beekeeper reported 90% fewer heat exhaustion episodes after switching to a mesh suit, with zero sting penetrations during 50+ hive checks. -

Glove Material Choice

A commercial apiary reduced hand injuries by 70% by equipping staff with nitrile-coated gloves, despite initial complaints about flexibility.

Ready to Upgrade Your Beekeeping Safety?

HONESTBEE’s wholesale-focused inventory delivers durable, climate-appropriate protective gear for distributors and commercial apiaries. From ventilated suits to sting-proof gloves, our products are tested in real-world conditions to ensure your team stays safe—and comfortable—season after season.

Explore our catalog today and outfit your operation with gear that balances protection and practicality.

Visual Guide

Related Products

- Yellow Plastic Bucket Pail Perch for Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- Metal Bee Hive Stand Bee Box Stand for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

Related Articles

- The Cold Deception: Why Beehive Wintering is About Moisture, Not Warmth

- How to Choose Beekeeping Gloves That Balance Protection and Precision

- The Interface Problem: How a Glove's Design Dictates a Beekeeper's Success

- Essential Beekeeping Tools: How Strategic Preparation Boosts Hive Health, Safety, and Honey Yields

- How to Determine the Optimal Beehive Stand Height for Comfort and Efficiency