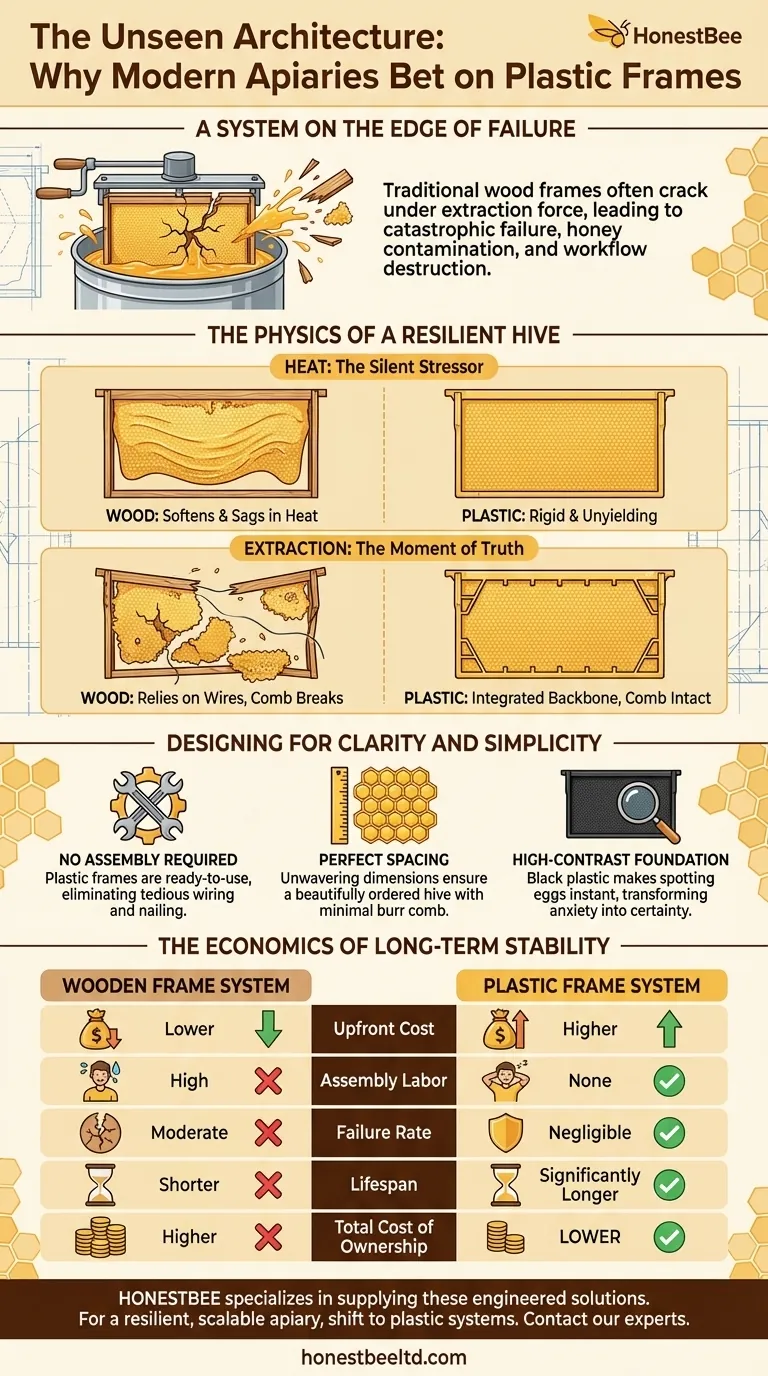

A System on the Edge of Failure

Imagine the scene. It's late summer, the air thick with the smell of honey. Hours of work have led to this moment: the extraction. As the centrifuge spins, a sudden, sickening crack echoes in the room. A wooden frame, weakened by heat and stressed by the immense rotational force, has just disintegrated.

The result is a catastrophe in miniature. A slurry of honey, splintered wood, and ruined beeswax coats the inside of the extractor. The bees' intricate work is destroyed, the honey is contaminated, and the beekeeper's workflow grinds to a halt.

This isn't a rare accident. It's a predictable failure point in a system built on traditional materials. The debate between wood and plastic frames isn't about nostalgia versus progress; it's a fundamental decision about risk management, efficiency, and the psychology of control.

The Physics of a Resilient Hive

A beehive is a marvel of engineering, but it operates within tight physical tolerances. The structure we provide for the colony can either buffer it from stress or become a point of weakness.

Heat: The Silent Stressor

In the peak of summer, a wooden hive is an oven. Wax foundation, the delicate sheet upon which bees build their comb, can soften, sag, and stretch under its own weight. This slow-motion collapse forces the colony to expend precious energy on constant repairs instead of foraging or raising brood.

Plastic frames are immune to this. They provide a rigid, unyielding foundation that remains perfectly flat and stable, even in scorching heat. This isn't just about preventing catastrophic failure; it's about providing the consistency bees need to thrive.

Extraction: The Moment of Truth

The honey extractor is the ultimate stress test. It subjects the comb to forces it never experiences in nature. While wooden frames rely on wires to brace the wax, plastic frames possess an integrated, rigid structure.

This design difference is critical. A plastic frame provides a solid backbone, ensuring the comb remains intact, preserving the bees' architecture for immediate reuse. This dramatically increases the speed of the harvest and reduces honey loss.

Designing for Clarity and Simplicity

A beekeeper’s most valuable resource is not time, but attention. Every task that introduces complexity or ambiguity drains this resource. Plastic frames are engineered to reduce this cognitive load.

From Assembly Line to Action

Wooden frames arrive as a box of parts. They demand assembly, nailing, gluing, and the tedious task of wiring and embedding wax foundation. Each step is a potential point of error.

Plastic frames, especially single-piece molded designs, eliminate this entirely. They are ready to use out of the box. This shift from "builder" to "manager" allows the beekeeper to focus on the health of the bees, not on equipment assembly.

The Power of Perfect Spacing

Bees build their world around a precise measurement known as "bee space." Mass-produced plastic frames adhere to exact, unwavering dimensions. This guarantees a perfect fit, every time.

The result is a beautifully ordered hive. It minimizes the growth of burr comb and propolis bridges, making hive inspections faster, less disruptive for the bees, and far less frustrating for the beekeeper.

Seeing is Believing

One of the most stressful tasks in beekeeping is confirming the queen is healthy and laying. On the pale yellow of natural wax, spotting tiny, rice-grain-sized eggs can be an exercise in futility.

Black plastic foundation provides a high-contrast background that makes fresh white eggs pop. An anxious, five-minute search becomes a confident, 30-second glance. This simple design choice transforms a crucial diagnostic check from a source of anxiety into a point of certainty.

The Economics of Long-Term Stability

It's easy to compare the upfront cost of a single plastic frame to its wooden counterpart and draw the wrong conclusion. The true cost of equipment is measured over its entire lifecycle.

Plastic is an investment in durability. It doesn't warp, split, or rot. It stands up to pests like wax moths that can tunnel through and destroy wax comb. This longevity fundamentally changes the economic equation.

| Metric | Wooden Frame System | Plastic Frame System |

|---|---|---|

| Upfront Cost | Lower | Higher |

| Assembly Labor | High (Recurring) | None |

| Failure Rate | Moderate | Negligible |

| Lifespan | Shorter | Significantly Longer |

| Total Cost of Ownership | Higher | Lower |

For commercial apiaries and distributors, where reliability and operational efficiency are paramount, the choice is clear. The slightly higher initial price of plastic is insurance against lost time, lost product, and the recurring cost of replacement. HONESTBEE specializes in supplying these engineered solutions, providing the robust, ready-to-use plastic frames that modern beekeeping operations depend on.

To build a more resilient and efficient apiary that scales with your ambitions, the conversation must shift from materials to systems. For wholesale inquiries about building a better system, Contact Our Experts.

Visual Guide

Related Products

- Professional Insulated Plastic Bee Hives

- 7 x Auto Bee Flow Hive Frames Plastic Beekeeping Hive Box Supplies

- Yellow Plastic Bucket Pail Perch for Beekeeping

- Plastic Honey Comb Frames Cassette Box for Honey

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

Related Articles

- Comprehensive Guide to Attracting Bees to a Hive

- How to Choose Between Top Bar and Langstroth Hives for Effortless Beekeeping

- Why Your Bee Boxes Don't Match: The Secret to Flawless Apiary Scaling

- How to Time Hive Insulation for Maximum Winter Bee Survival

- The Unclimbable Fortress: A Systems Approach to Protecting Hives from Ants