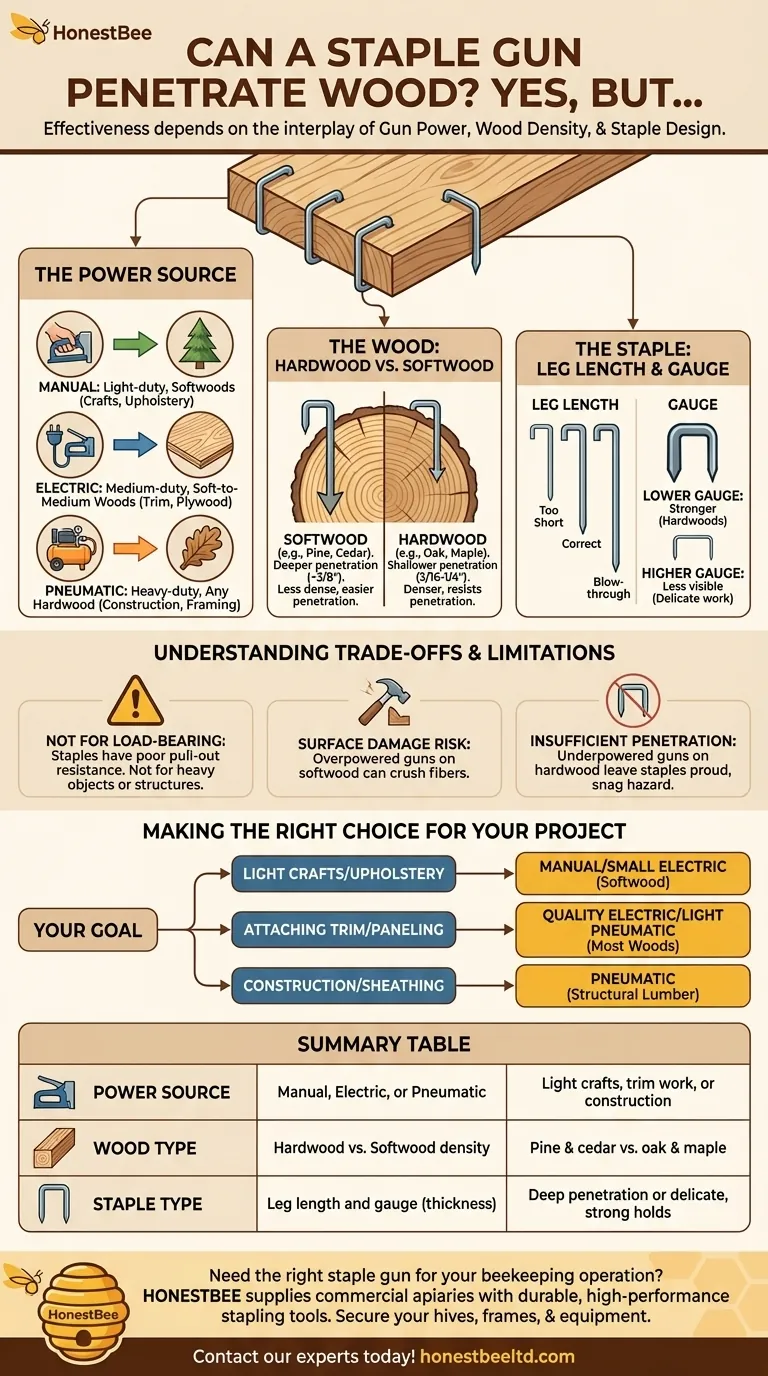

Yes, a staple gun can absolutely penetrate wood. However, its effectiveness depends entirely on the type of staple gun, the type of staple, and the hardness of the wood itself. For softer woods, even a basic manual staple gun can work, while harder woods require the force of an electric or pneumatic model to achieve proper penetration.

The core issue isn't whether a staple gun can penetrate wood, but rather matching the power of the tool and the specifications of the staple to the density of the wood to ensure a secure and clean hold for your specific project.

The Three Factors of Successful Stapling

To determine if a staple gun is the right tool, you must consider the interplay between the gun's power, the wood's density, and the staple's design.

The Power Source: Manual, Electric, or Pneumatic

Not all staple guns are created equal. Their power source is the primary indicator of their capability.

- Manual Staple Guns: These are best for light-duty tasks like crafts or upholstery on softwoods like pine. They lack the driving force for dense hardwoods.

- Electric Staple Guns: Offering more power and consistency than manual models, these are suitable for tasks like fastening trim or working with plywood and other soft to medium-hardwoods.

- Pneumatic Staple Guns: These are the most powerful, using compressed air to drive staples with significant force. They are the go-to choice for construction, framing, and reliably fastening materials to any hardwood.

The Wood: Hardwood vs. Softwood

The type of wood is the resisting force your staple must overcome.

- Softwoods (pine, cedar, fir) are less dense, allowing staples to penetrate easily. A deeper penetration of up to 3/8 of an inch is often required for a strong hold.

- Hardwoods (oak, maple, cherry) are much denser and resist penetration. A powerful gun is required, and a shallower penetration of 3/16 to 1/4 of an inch is typically sufficient for a firm grip. Forcing a staple too deep into hardwood can damage the wood fibers.

The Staple: Leg Length and Gauge

The staple itself is the final piece of the puzzle. Using the wrong staple is a common point of failure.

- Leg Length: The length must be appropriate for the material thickness and the required penetration depth. A staple that is too short won't hold, and one that is too long may go all the way through your material ("blow-through").

- Gauge (Thickness): Thicker, lower-gauge staples are stronger and less likely to deform when driven into hardwood. Finer, higher-gauge staples are less visible and ideal for delicate work or upholstery.

Understanding the Trade-offs and Limitations

While versatile, a staple gun is not a universal solution. Understanding its limits is key to avoiding frustration and project failure.

When a Staple Isn't Enough

Staples are fasteners, not structural supports. Their primary strength is in shear (preventing sliding) and holding thin materials in place. They have very poor pull-out resistance compared to screws or even nails. Never use staples for load-bearing applications, such as hanging heavy objects or assembling structural frames.

The Risk of Surface Damage

Using a gun that is too powerful for the wood can be as problematic as using one that's too weak. An overpowered shot on softwood can drive the staple too deep, crushing the wood fibers and compromising the hold.

The Problem of Insufficient Penetration

Conversely, using an underpowered staple gun on hardwood will result in the staple crown sitting proud of the surface. This creates a snag hazard, looks unprofessional, and indicates a weak connection that will likely fail.

Making the Right Choice for Your Project

Use your goal to guide your tool selection.

- If your primary focus is light crafts or upholstery: A manual or small electric staple gun is sufficient for fastening fabric to softwood frames.

- If your primary focus is attaching trim or paneling: A quality electric or light-duty pneumatic staple gun will provide the consistency needed for a clean finish on most woods.

- If your primary focus is construction or fastening sheathing: A pneumatic staple gun is the only reliable option to ensure proper, consistent penetration into structural lumber.

Ultimately, success comes from viewing the gun, the staple, and the wood as a single, interconnected system.

Summary Table:

| Factor | Key Consideration | Best For |

|---|---|---|

| Power Source | Manual, Electric, or Pneumatic | Light crafts, trim work, or construction |

| Wood Type | Hardwood vs. Softwood density | Pine & cedar vs. oak & maple |

| Staple Type | Leg length and gauge (thickness) | Deep penetration or delicate, strong holds |

Need the right staple gun for your beekeeping operation? Whether you're building hive bodies, frames, or other equipment, HONESTBEE supplies commercial apiaries and distributors with durable, high-performance stapling tools. Get a secure, professional-grade hold on any wood. Contact our experts today to find the perfect solution for your needs!

Visual Guide

Related Products

- Modern Honeycomb Pattern Wooden Honey Dipper for Stirring and Drizzling

- One Hand Yellow Queen Marking Catcher Tube Cage Beekeeper Tool Accessory for Queen Bee

- Heavy-Duty Bee Smoker with Durable Plastic Bellows for Beekeeping

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

- Automatic Honey Flow Beehive 4 Frame Mini Hive for Beekeeping

People Also Ask

- How do modern beehives compare to traditional beehives in honey production efficiency? Maximize Your Apiary's Output

- What is the significance of standardized hive-making machines? Precision & Scalability in Modern Beekeeping

- How do industrial beehive manufacturing machines support the large-scale expansion of beekeeping operations? Scale Up Now

- How does industrial-grade beehive manufacturing machinery facilitate large-scale honey production infrastructure?

- What role does high-precision beehive manufacturing machinery play? Unlock Scalable Commercial Beekeeping

- What are the power requirements and control system for the Bee Box machine? Optimize Your Apiary Equipment Production

- Why are automated woodworking hive-making machines essential for large-scale apitourism? Boost Precision and Scale

- How does professional hive-making equipment affect honey purity? Enhance Quality with Standardized Apiary Hardware